Cavity magnetron

The cavity magnetron is a high-powered vacuum tube that generates microwaves using the interaction of a stream of electrons with a magnetic field. The 'resonant' cavity magnetron variant of the earlier magnetron tube was invented by Randall and Boot in 1940.[1] The high power of pulses from the cavity magnetron made centimetre-band radar practical. Shorter wavelength radars allowed detection of smaller objects. The compact cavity magnetron tube drastically reduced the size of radar sets[2] so that they could be installed in anti-submarine aircraft[3] and escort ships.[2] At present, cavity magnetrons are commonly used in microwave ovens and in various radar applications.[4]Construction and operation

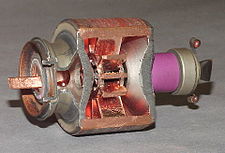

A similar magnetron with a different section removed (magnet is not shown).

The magnetron is a self-oscillating device requiring no external elements other than a power supply. A well-defined threshold anode voltage must be applied before oscillation will build up; this voltage is a function of the dimensions of the resonant cavity, and the applied magnetic field. In pulsed applications there is a delay of several cycles before the oscillator achieves full peak power, and the build-up of anode voltage must be coordinated with the build-up of oscillator output. [5]

The magnetron is a fairly efficient device. In a microwave oven, for instance, a 1.1 kilowatt input will generally create about 700 watt of microwave power, an efficiency of around 65%. (The high-voltage and the properties of the cathode determine the power of a magnetron.) Large S-band magnetrons can produce up to 2.5 megawatts peak power with an average power of 3.75 kW.[5] Large magnetrons can be water cooled. The magnetron remains in widespread use in roles which require high power, but where precise frequency control is unimportant.

Applications

Radar

In radar devices the waveguide is connected to an antenna. The magnetron is operated with very short pulses of applied voltage, resulting in a short pulse of high power microwave energy being radiated. As in all radar systems, the radiation reflected off a target is analyzed to produce a radar map on a screen.Several characteristics of the magnetron's power output conspire to make radar use of the device somewhat problematic. The first of these factors is the magnetron's inherent instability in its transmitter frequency. This instability is noted not only as a frequency shift from one pulse to the next, but also a frequency shift within an individual transmitter pulse. The second factor is that the energy of the transmitted pulse is spread over a wide frequency spectrum, which makes necessary its receiver to have a corresponding wide selectivity. This wide selectivity permits ambient electrical noise to be accepted into the receiver, thus obscuring somewhat the received radar echoes, thereby reducing overall radar performance. The third factor, depending on application, is the radiation hazard caused by the use of high power electromagnetic radiation. In some applications, for example a marine radar mounted on a recreational vessel, a radar with a magnetron output of 2 to 4 kilowatts is often found mounted very near an area occupied by crew or passengers. In practical use, these factors have been overcome, or merely accepted, and there are today thousands of magnetron aviation and marine radar units in service. Recent advances in aviation weather avoidance radar and in marine radar have successfully implemented solid-state transmitters that eliminate the magnetron entirely.

Heating

In microwave ovens the waveguide leads to a radio frequency-transparent port into the cooking chamber.Lighting

In microwave-excited lighting systems, such as a sulfur lamp, a magnetron provides the microwave field that is passed through a waveguide to the lighting cavity containing the light-emitting substance (e.g., sulfur, metal halides, etc.)History

The first simple, two-pole magnetron was developed in 1920 by Albert Hull[6] at General Electric's Research Laboratories (Schenectady, New York), as an outgrowth of his work on the magnetic control of vacuum tubes in an attempt to work around the patents held by Lee De Forest on electrostatic control.Hull's magnetron was not originally intended to generate VHF (very-high-frequency) electromagnetic waves. However, in 1924, Czech physicist August Žáček[7] (1886-1961) and German physicist Erich Habann[8] (1892-1968) independently discovered that the magnetron could generate waves of 100 megahertz to 1 gigahertz. Žáček, a professor at Prague's Charles University, published first; however, he published in a journal with a small circulation and thus attracted little attention.[9] Habann, a student at the University of Jena, investigated the magnetron for his doctoral dissertation of 1924.[10] Throughout the 1920s, Hull and other researchers around the world worked to develop the magnetron.[11][12][13] Most of these early magnetrons were glass vacuum tubes with multiple anodes. However, the two-pole magnetron, also known as a split-anode magnetron, had relatively low efficiency. The cavity version (properly referred to as a resonant-cavity magnetron) proved to be far more useful.

While radar was being developed during World War II, there arose an urgent need for a high-power microwave generator that worked at shorter wavelengths (around 10 cm (3 GHz)) rather than the 150 cm (200 MHz) that was available from tube-based generators of the time. It was known that a multi-cavity resonant magnetron had been developed and patented in 1935 by Hans Hollmann in Berlin.[14] However, the German military considered its frequency drift to be undesirable and based their radar systems on the klystron instead. But klystrons could not achieve the high power output that magnetrons eventually reached. This was one reason that German night fighter radars were not a match for their British counterparts[15].

In 1940, at the University of Birmingham in the United Kingdom, John Randall and Harry Boot produced a working prototype similar to Hollman's cavity magnetron, but added liquid cooling and a stronger cavity. Randall and Boot soon managed to increase its power output 100 fold. Instead of abandoning the magnetron due to its frequency instability, they sampled the output signal and synchronized their receiver to whatever frequency was actually being generated. In 1941, the problem of frequency instability was solved by coupling alternate cavities within the magnetron.

Because France had just fallen to the Nazis and Britain had no money to develop the magnetron on a massive scale, Churchill agreed that Sir Henry Tizard should offer the magnetron to the Americans in exchange for their financial and industrial help (the Tizard Mission). An early 6 kW version, built in England by the General Electric Company Research Laboratories, Wembley, London (not to be confused with the similarly named American company General Electric), was given to the US government in September 1940. At the time the most powerful equivalent microwave producer available in the US (a klystron) had a power of only ten watts. The cavity magnetron was widely used during World War II in microwave radar equipment and is often credited with giving Allied radar a considerable performance advantage over German and Japanese radars, thus directly influencing the outcome of the war. It was later described as "the most valuable cargo ever brought to our shores".[16]

The Bell Telephone Laboratories made a producible version from the magnetron delivered to America by the Tizard Mission, and before the end of 1940, the Radiation Laboratory had been set up on the campus of the Massachusetts Institute of Technology to develop various types of radar using the magnetron. By early 1941, portable centimetric airborne radars were being tested in American and British planes.[17] In late 1941, the Telecommunications Research Establishment in Great Britain used the magnetron to develop a revolutionary airborne, ground-mapping radar codenamed H2S. The H2S radar was in part developed by Alan Blumlein and Bernard Lovell.

Centimetric radar, made possible by the cavity magnetron, allowed for the detection of much smaller objects and the use of much smaller antennas. The combination of small-cavity magnetrons, small antennas, and high resolution allowed small, high quality radars to be installed in aircraft. They could be used by maritime patrol aircraft to detect objects as small as a submarine periscope, which allowed aircraft to attack and destroy submerged submarines which had previously been undetectable from the air. Centimetric contour mapping radars like H2S improved the accuracy of Allied bombers used in the strategic bombing campaign. Centimetric gun-laying radars were likewise far more accurate than the older technology. They made the big-gunned Allied battleships more deadly and, along with the newly developed proximity fuse, made anti-aircraft guns much more dangerous to attacking aircraft. The two coupled together and used by anti-aircraft batteries, placed along the flight path of German V-1 flying bombs on their way to London, are credited with destroying many of the flying bombs before they reached their target.

Since then, many millions of cavity magnetrons have been manufactured; while some have been for radar the vast majority have been for microwave ovens. The use in radar itself has dwindled to some extent, as more accurate signals have generally been needed and developers have moved to klystron and traveling-wave tube systems for these needs.

Health hazards

There is also a considerable electrical hazard around magnetrons, as they require a high voltage power supply. Operating a magnetron with the protective covers removed and interlocks bypassed should therefore be avoided.

Some magnetrons have beryllium oxide (beryllia) ceramic insulators, which is dangerous if crushed and inhaled, or otherwise ingested. Single or chronic exposure can lead to berylliosis, an incurable lung condition. In addition, beryllia is listed as a confirmed human carcinogen by the IARC; therefore, broken ceramic insulators or magnetrons should not be directly handled.

--

Teone Salazar

Comunicaciones de Radio Frecuencia

http://en.wikipedia.org/wiki/Cavity_magnetron

This is really amazing blog...thanks for sharing Magnetron price in India

ResponderEliminarAwesome blog about waveguide components

ResponderEliminar